With house prices increasing and the cost of moving considerable, more and more people are looking to refurbish their existing property to turn it into a dream home or, at the very least, a home more suited to their needs and lifestyle. For a number of home owners and some social housing providers, this is also the ideal opportunity to incorporate ‘green’ technologies and enhance the sustainability of their property, whether that be to save money on energy bills or for environmental concerns. With the recent introduction of the Green Deal, which is essentially a loan paid back over time to help make energy-saving improvements to a home, and increases in energy prices - interest in this field has never been higher.

There are many well documented approaches to improving a property’s energy retention, including adding insulation, draught-proofing, double glazing and fitting solar panels. However the question that is raised time and time again is ‘can I fit a heat recovery system in an existing property’?

A Mechanical Ventilation with Heat Recovery (MVHR) system efficiently pre-warms fresh filtered air drawn into a building with the heat extracted from stale air leaving the building - using a heat exchanger up to 95% of waste heat can be recovered by this means. The fresh warm air is then distributed around the living areas of the home.

MVHR is not a substitute for heating (especially not in our climate!), but it can effectively reduce the amount of heat required in the property and has many health benefits ranging from the circulation of clean warm air and the filtration of incoming air. It’s also a relatively low cost means of moving towards complying with the Code for Sustainable Homes and lowering a property’s Dwelling Emission Rate.

As a result, MVHR is very popular in new builds and many architects, consultants, contractors and home owners are keen to also reap the benefits in existing properties.

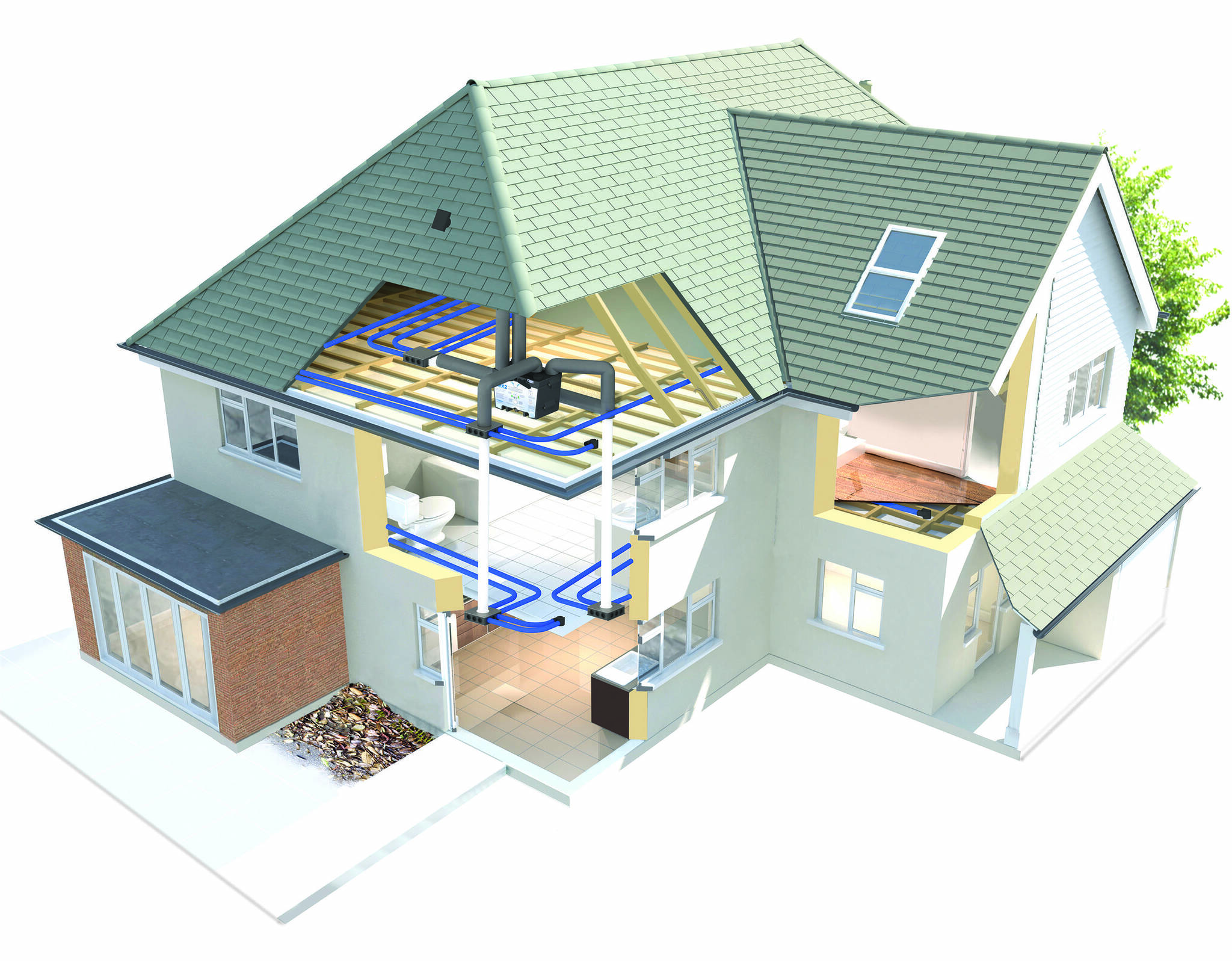

An MVHR system consists of the actual unit, which houses the heat exchanger and two duct runs connecting to outside, one for incoming fresh air and one for exhaust air. Further duct runs are then connected to all of the ‘habitable’ and ‘wet’ rooms. These runs are terminated with a ceiling-mounted adjustable air valve or architectural grille at each end of a room to assist in balancing the air flow around the dwelling. Finally a condensate drainage kit with a trap is then fitted to the MVHR unit and powered by an electrical supply.

The MVHR units are often relatively compact and designed for either loft or wall mounting; the latter are usually conveniently hidden away in a cupboard. Finding space for the unit isn’t normally an issue in a refurbishment project. Nor is there usually any challenge with the duct runs connecting to the outside of the property as these can terminate either through the roof or wall. Where challenges are most likely to arise are with the internal ducting: where to put it?

Ducting for Mechanical Ventilation with Heat Recovery systems is normally Ø125 or 150mm (or the equivalent in rectangular) so it can be difficult to hide the duct behind trunking or fit between tight spaces. The ducting system itself also needs to be carefully designed to maximise air flow and reduce air leakage, which means avoiding too many sharp bends. All this has an impact on where the duct runs go, but home owners are unlikely to want ducting on show in their newly refurbished property.

There are options for concealing the ducting behind bedroom wardrobes, cupboards, etc but not always possible in every room, so this needs to be given serious thought. If however the refurbishment is a major one, then you can build risers and accommodate the ducting that way.

Alternatively you could use a Radial semi-rigid ducting system instead. Unlike traditional branch based ducting systems, Radial systems allow each room vent to be served by single or twin duct runs which connect directly to the central distribution system, evenly splitting the air from the MVHR unit. In the case of Polypipe’s Domus Radial system, this is ideal for small spaces as it uses Ø75mm semi-rigid ducting and has an ultra slim 125mm deep manifold which can easily be fitted between loft joists or in tight spaces. The small manifold size also allows for greater location flexibility, removing the need to place the manifold adjacent to the centralised appliance. The manifold can also be used with Domus rigid branch ducting, providing greater flexibility for the installer.

If the property is a bungalow, then the ducting is rarely a problem, so Mechanical Ventilation with Heat Recovery systems may well be worth considering.

If you can accommodate the ducting in the property being refurbished, you still need to consider one other vital factor: will it be effective? By this I am not questioning the amount of heat recovered by an MVHR system or the quality of individual units; nor am I questioning the installation techniques (that’s for another article). Instead I am referring to the degree of air tightness of the property in question. For the large majority of older properties, draughts are a way of life.

MVHR systems work by using the heat contained in the atmosphere in a building; if all warm air is exiting through the gaps under doors or around windows, there’s nothing left for the MVHR system to use.

So it’s essential you check the property’s air leakage, or permeability as it is also known. There are many companies that provide this service. It involves temporary sealing all holes that are meant to be in the fabric of the property, such as trickle vents and even water traps. A fan is used to pressurise the property to 50Pa. When it is stable at 50Pa, the flow rate required to maintain the pressure is recorded in m³/h per square metre of floor area. This figure is then divided by the total area of the property in m² to provide the leakage rate. If all this sounds rather scary and you think your home might be in danger of bursting, fear not! To put the pressure level in context, you would normally fill your car tyres to a pressure of 200000Pa, so 50Pa in comparison is nothing to worry about!

Building Regulations sets the allowable maximum are leakage at 10m³/h. Approved Document F (Ventilation) of the Building Regulations classes <5 as an airtight property and >5 as a leaky property. For MVHR to work effectively, the leakage rate should be ≤3. Anything above that is questionable as to whether you will reap any tangible benefits from the system.

This isn’t unachievable in a refurbishment project (and just as a matter of interest, a Passivhaus property has a requirement of 0.6m³/h which is very challenging!), but it does mean that MVHR systems are more effective in relatively new properties or ones that are undergoing a major refit, rather than a single room refurbishment.

MVHR systems have been on the market for some time, but they have only recently become prevalent with the move towards greater sustainability in house building. With many households now deciding to stay put and refurbish their properties, this sector is also looking to benefit from the energy saving and health qualities MVHR systems can bring. But be sure to do your homework first, taking into account the possible duct runs and what needs to be done to reduce the building’s air leakage. Only then will you have a truly effective MVHR system.

Polypipe Ventilation provides customers with a complete sustainable ventilation package, with ducting and appliance working in harmony, to meet the most demanding of energy efficiency targets. For more information please call 03443 715523 or email vent.marketing@polypipe.com.