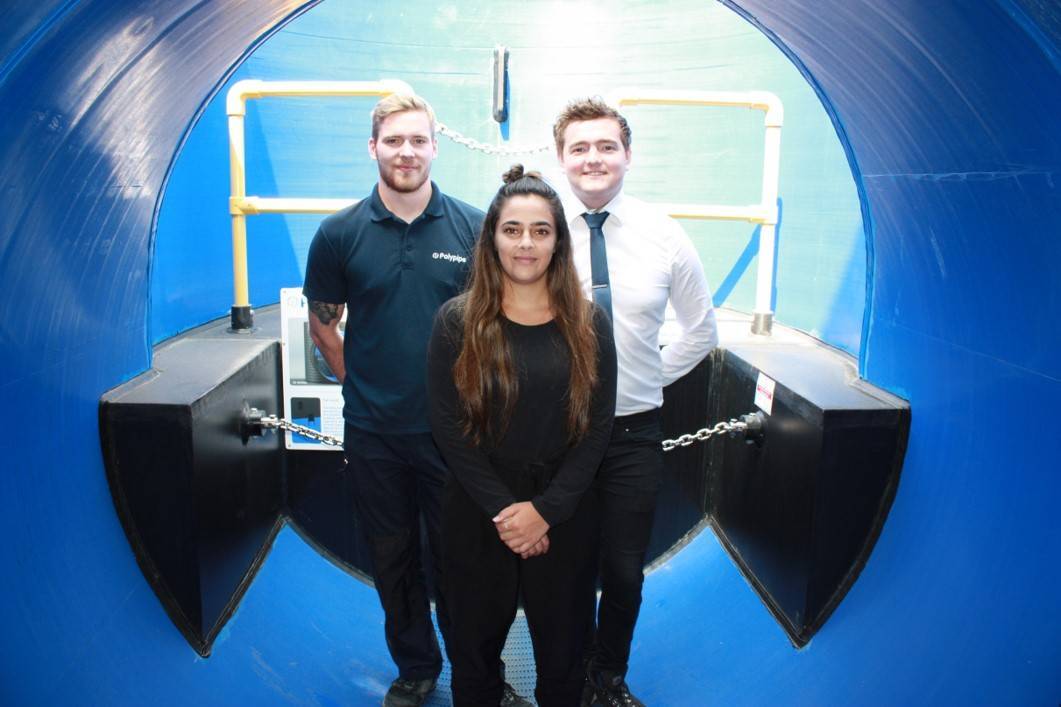

Six apprentices from multiple departments at Polypipe Civils came together to pull off the biggest apprentice challenge yet; a mission to show endurance, versatility and strong team working skills. A marketing apprentice learnt how to weld, an engineering apprentice learnt the power of production and a business admin apprentice learnt the ropes when it came to fabrications.

After two months of planning, production and execution the project was deemed “a resounding success” by Loughborough’s Operations Manager, Neville Blowers.

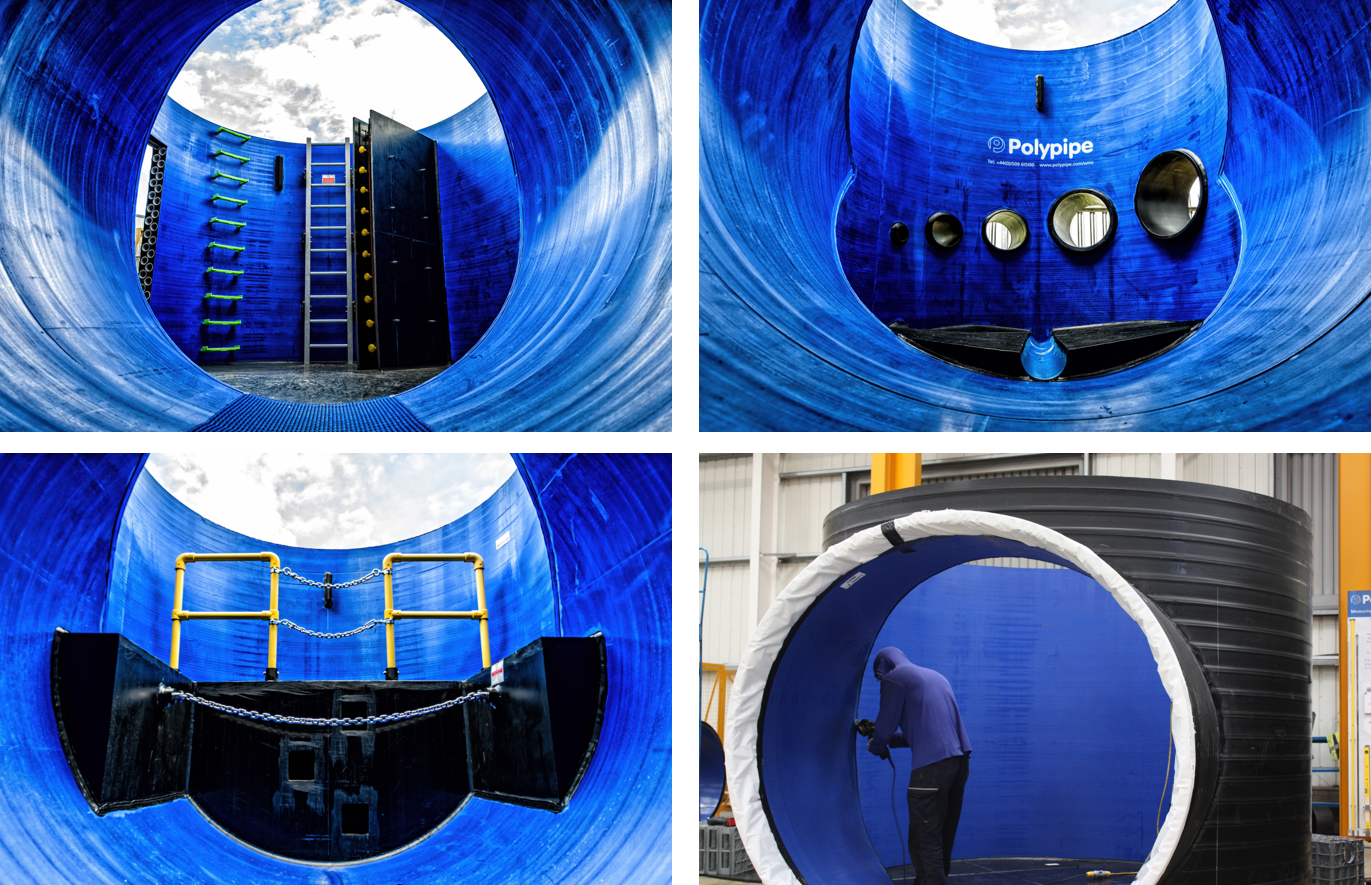

The aim of the project was to create a display of Polypipe’s Water Management Solutions offering, including, Permavoid, Permachannel, as well as a display of a Ridgistorm-XL piping system with multiple chambers containing: a penstock, flap valve, guard rails, ladders, safety chains, toe holds, head walls, a vortex flow control and lifting points on the outside of the chambers.

For the apprentices it was about them stepping out of their comfort zones and learning about all aspects of the Polypipe business.

Neville Blowers, Operations Manager:

“The project wasn’t simply about tasking our apprentices with a hands on project, but to show them the scalability and size of our products. It’s a display we now show our customers who visit our manufacturing facility, to show them exactly what we offer. The project was such a success and all apprentices were offered full time roles with us.”

Josh McMeckan, Ridgistorm-XL Project Scheduler:

“We designed scenarios and problems for the apprentices to overcome and understand the challenges everyone at Polypipe faces on a day to day basis. They thought of practical and reasonable solutions; I was very impressed with the way they organised the project and the care they had in every step of the way.”

Meet the apprentices, mini interviews

Olivia Carson

What apprenticeship have you done and what do you do now?

My apprenticeship was the Level 3 NVQ Diploma in Marketing and Level 3 Certificate in Principles of Marketing. Since securing a permanent role in the marketing team at Loughborough I have completed the Level 3 CIM Foundation Certificate in Marketing.

What have you learnt in the past year whilst working at Polypipe?

I have learnt a lot over the past year, such as communicating better with different departments and managing mini projects from start to finish.

What skills did you learn at the apprentice project in 2017 that you can now use in your job?

The skills that I learnt whilst doing the apprentice project was to manage deadlines better. In order to make sure the project ran smoothly and all stages were complete, I updated a Gantt chart daily and then encouraged the rest of the project team to meet their deadlines.

If you could have three talents, what would they be?

- To be artistic, I would love to be able to draw and paint

- To play the piano

- To be psychic

If you were stranded on a desert island, what three items would you want with you?

- The food I like

- The drinks I like

- A phone that works - to ring for help!

Brandon Shreeves

What apprenticeship have you done and what do you do now?

I have completed a business administration apprenticeship and I now work in the operation’s department as a project planner and scheduling apprentice.

What have you learnt in the past year whilst working at Polypipe?

I have integrated myself into a team which has led to positive results. Additionally, I realise the importance of good communication in all its forms and have developed these skills throughout my time at Polypipe.

What skills did you learn at the apprentice project in 2017 that you can now use in your job?

I learnt how to develop conceptual ideas into reality while working to a specific brief and deadlines. I believe the skills I have learned are transferrable to a range of processes which need to harness creativity but also require logical thinking and methodical practices.

If you could have three talents, what would they be?

- To be fluent in another language

- Play the cello

- To be able to skateboard

If you were stranded on a desert island, what three items would you want with you?

- Lots of beer; either Coors Light, Budweiser or Pedigree

- A comfortable chair

- My IPod + headphones

Brooklyn Buckby

What apprenticeship have you done and what do you do now?

During my apprenticeship I was working in fabrications and pipe production as an advanced fabricator. I studied at Loughborough college for 3 years whilst also completing a Level 3 NVQ in fabrication and welding here at Polypipe. Since finishing my apprenticeship I have moved into a new department and am now a Quality and Process Technician.

What have you learnt in the past year whilst working at Polypipe?

In the past year I have learnt a lot as I moved into a completely new job role, I am now at the point where I can perform my job efficiently and have a much better understanding of the industry and the products that we produce here on site. I have learned a lot about ISO 9001 and ISO 14001 certifications and BBA product approvals throughout the year, and also how to best analyse processes and improve them where possible.

What skills did you learn at the apprentice project in 2017 that you can now use in your job?

Having to work with a wide array of people all at different levels of management meant that I was able to get a good understanding of the amount of work required on a project like this. It also gave me an insight into other job roles within the business and this was my first experience with a quality role as I worked closely with the quality apprentice on this project.

If you were stranded on a desert island, what three items would you want with you?

- A boat

- The Captain of the boat

- A map